In the first half of 2022, the shipment of the global New Energy Vehicle (NEV) market took off, and the sales of NEVs in mainland China in the first half of the year were particularly prominent, creating an astonishing result of a year-on-year increase of more than 100%. When new energy vehicles become a household topic, people's requirements for battery systems become increasingly high. They expect manufacturers not only to improve battery life, but also to ensure safety and stability. As a result, a major innovative technology in the industry is about to emerge, that is, wBMS, or wireless battery management system.

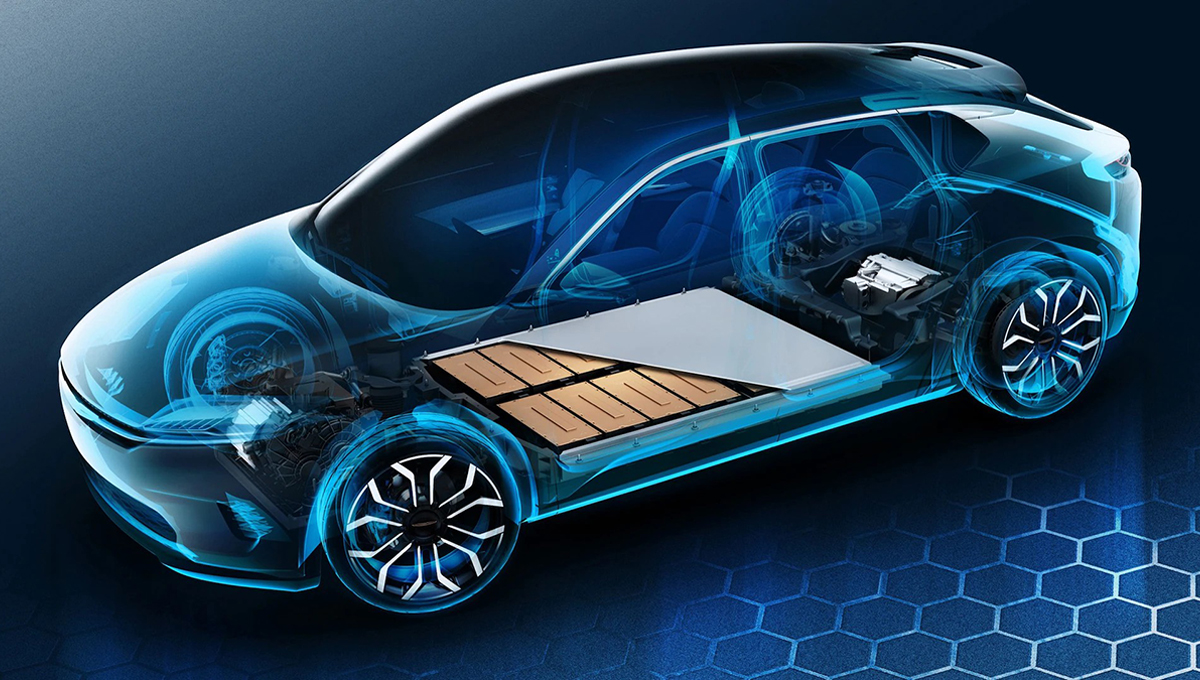

The cost of BMS accounts for about 20% of the power battery of NEVs. The traditional BMS connects the battery packs with cables, and then bridges them with daisy chain interfaces. The use of cables and mechanical interfaces is space consuming, which actually squeezes the room for battery energy density improvement. The wireless BMS replaces the traditional ring circuit by deploying wireless modules on the BMS host and the battery pack node, realizing the star + ad hoc network mode for necessary communication of battery management. The wireless method not only increases the energy density improvement space, but also greatly reduces the labor in the battery assembly stage. And with wireless solutions manufacturers does not need to consider investment big money on isolation between the high and low voltage circuits in the battery.

In the traditional mode, in event of an accident or aging caused by long distance riding, some cable might get broken or contact of some interface would become poor. It is easy to cause the power battery system to disfunction. In that case, the power battery needs to be replaced as a whole. The potential economic loss to the car owner is considerable. The wireless method does not have the problem of wire and interface failure, and because of its wireless characteristics, it naturally has the advantage of modularization. Even if there is a problem with a certain part of the battery pack, you can just take out the faulty battery pack for replacement without disposing the entire power battery.

Due to the above-mentioned advantages, leading car makers began to consider wireless BMS technology from 2019. So far available or upcoming models with wireless BMS technology include: BMW i3 (2022), GM's Hummer EV (2024).

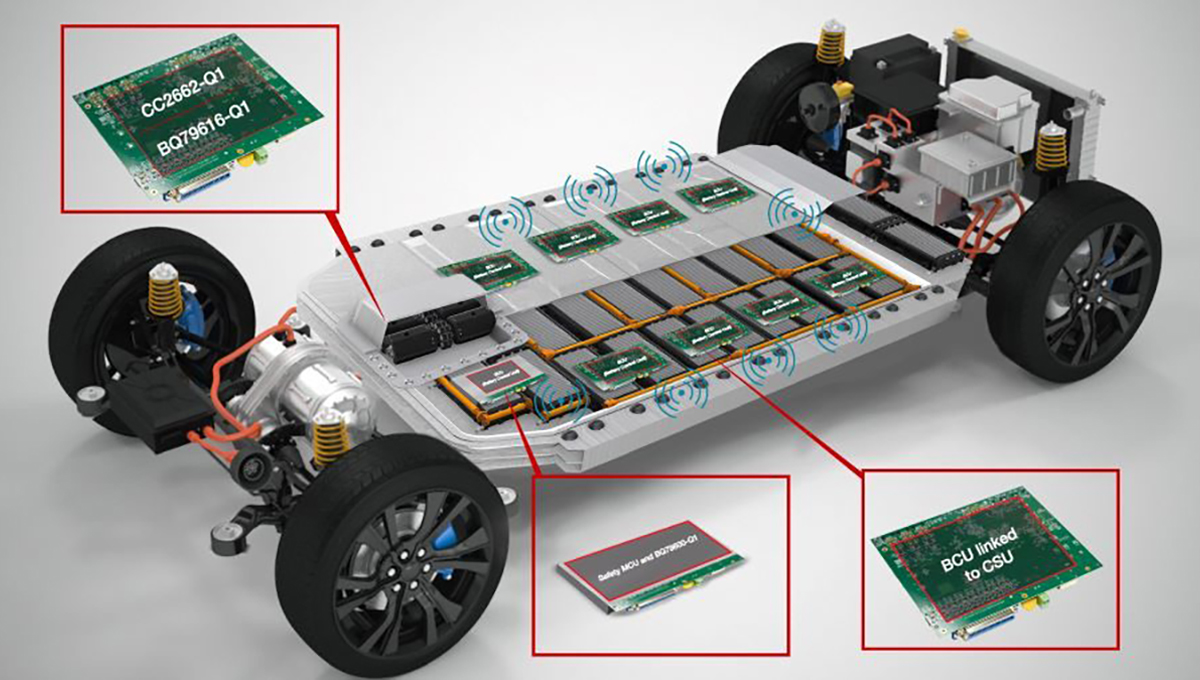

Texas Instruments, which is deeply involved in the field of automotive electronics, took the lead in launching the CC2662R-Q1, the world's first wBMS SoC solution that complies with ISO 26262 ASIL D standard. The chip deploys the TI's proprietary Simplelink wBMS protocol over the 2.4GHz band. The solution can manage and support up to 100 nodes, and specified to couple with BQ79616-Q1 battery monitor, it can be used for different configurations, such as 16, 32, and 64-cell battery systems.

The wireless approach in which the battery module transmits battery data directly to the BMS MCU overcomes the challenges inherent for wired communication. To achieve the performance of the wired solution in communication, the key problem that needs to be solved in the wireless BMS solution is the availability of a BMS private network. TI's solution builds a wireless network over the 2.4-GHz band that must be readily available, ie, as soon as the EV starts, the network must be up and ready for battery management. TI's Simplelink wBMS protocol was defined and developed to ensure that the network is instantly available and reliable at all times. This ensures that when the vehicle is started with one key at any time, the battery and BMS parts are immediately connected to the network and enter the working state immediately.

The usage scenarios of power batteries demand the wireless BMS for superior availability. Availability is defined as a ratio of the time of reliable data transmission between wireless connected nodes and the wireless master over the whole up time of the system. TI's wBMS architecture can increase the availability of BMS communication systems to 99.9999%. That is, for a network of 10 nodes, the TI Wireless BMS protocol can achieve a packet error rate of 10^-7 or higher. This means that in 52.222 hours of wireless BMS operation, node data is unavailable for only 100 milliseconds. The protocol also guarantees that the wireless BMS can work properly in challenging enclosure environments. This type of enclosure space is usually very narrow, and serious attenuation and reflection will occur when the signal bounces through the metal plate during transmission.

The wireless BMS technology can greatly improve the reliability and accuracy of cell management, improve the efficiency of PACK assembly, reduce the technical complexity and overall cost of PACK, and provide better intelligent management solutions for the future. Therefore, it has great commercial prospects.

As a wireless IoT technology provider, the RF-star has been supplying various wireless solutions for leading NEV brands in the past 8 years. Also, a veteran IDH of the Texas Instrument, RF-star is sparing no effort to promote wireless BMS to enable more NEV makers to leap forward in greener design.

For any questions, please don’t hesitate to contact the writer: richard.yan@szrfstar.com